Content

Thrust Bearings - ball bearings minneapolis

THE ADVANTAGES OF DEEP GROOVE ROUND BEARINGS

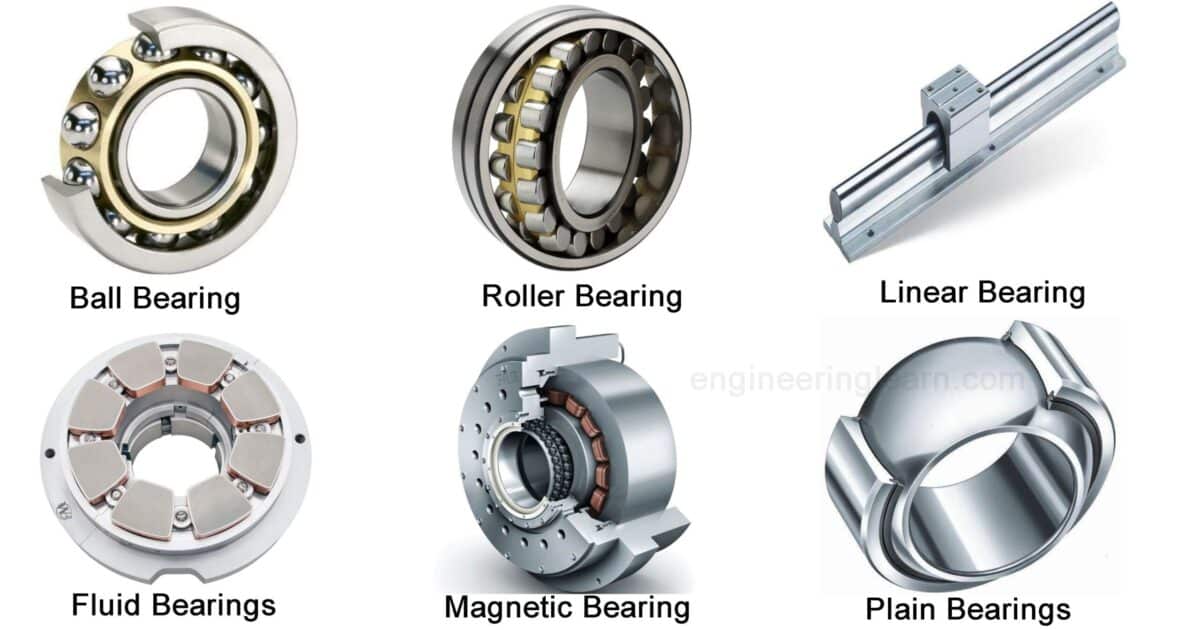

Rolling bearings are a crucial component of revolving or oscillating device components. They help sustain and direct rotational movement as well as transfer lots between different elements, such as axles, shafts, and wheels. Round bearings are a type of rolling bearing that enjoy rolling component. This ball beings in a ring raceway, or groove, causing a reasonably low call location. The reduced contact area decreases friction however limits the weight the bearing can carry. Sphere bearings are traditionally used in high-speed, low-load applications, where their lowered rubbing, noise, and vibration assistance protect against excess deterioration. Sphere bearings typically fit radial lots or loads that are perpendicular to the shaft. While some sphere bearing types can manage axial lots (parallel to the shaft), they're usually limited to extremely low carrying capacities.

What are Deep Groove Round Bearings?

Deep groove ball bearings are similar to traditional bearings however have raceways that closely fit the dimensions of the balls that run in them. These deep grooves cause balls that are more secure and can manage greater tons than shallow-groove bearings. They still offer reduced rubbing, and the deep groove additionally restricts resonance and sound while likewise providing the capability for some axial lots ability. If you've ever seen any type of type of ball bearing, chances are you were checking out a deep groove round bearing. These bearings are several of the most usual due to their flexibility, schedule, and also low rubbing. They're suitable for high rotational rates and also supply a number of advantages over other ball bearing types. These bearings can be found in a massive variety of styles, sizes, and load-bearing capacities, making them perfect for home or industrial use. Also, it's straightforward to replace traditional bearings with deep groove round bearings, which can improve the durability and performance of the maker.

Kinds Of Deep Groove Ball Bearings

Suppliers have actually fine-tuned the design of deep groove bearings over the years, resulting in several different kinds. These types are usually better fit to a certain application where a deep groove bearing isn't appropriate. Single-Row Deep Groove Round Bearings This is the normal deep groove sphere bearing that has a solitary raceway. These are generally robust and also made from long lasting products, making certain that these bearings have an extended service life. Single-row deep groove ball bearings are likewise subdivided right into various other kinds, varying from 3 mm to 400 mm birthed sizes, suitable for virtually any application. Some suppliers will certainly also offer slim, slim, broad, or miniature bearings depending upon customers' requirements.

- Koyo lately boosted their bearings dynamic load rankings by 25% because of constant improvements in making processes and also the tidiness of steel over the previous two decades.

- Straight Rails are ideal for relocating products through a manufacturing process with wonderful precision and also as little rubbing as feasible if creating, packaging, as well as distributing items.

- The sphere bearing must fit its application depending upon the discussed criteria.

- Food as well as beverage-- In the food and also drink industry, round bearings are utilized throughout different stages of making processes.

- Selecting crossbreed radial or angular call bearings over conventional steel bearings offers essential performance benefits.

- In many applications, one race is affixed to the revolving assembly (e.g. a shaft or center), and also the various other race is fixed.

Since deep more info groove sphere bearings need to stand up to extreme problems, producers also use ceramic-coated bearings to handle electrical pitting and high-temperature devices that can withstand as much as 660 degrees F. Among the latest growths in single-row deep groove sphere bearings is the sensor-bearing unit, which can determine the condition of the round bearing components. These devices are straightforward as well as easy to use and also can assist with rate noticing, angular setting measuring, and guiding, making them beneficial in electric motors, tractors, conveyors, and roadway rollers.

Kinds Of Straight Actuators - bearings minneapolis

Secured Deep Groove Round Bearings

Secured deep groove sphere bearings are similar to single-row bearings, except that they have steel or rubber guards installed on one or both sides of the bearing. These seals are pre-lubricated with grease to expand the life-span of the bearing. Numerous makers used covered ball bearings in contaminated environments that may or else affect the efficiency of the bearing. The shields assist the bearing preserve grease while likewise stopping any kind of pollutants from getting in the bearing itself. Bigger deep groove ball bearings might also use machined brass cages for high-speed applications, where the cage prevents undesirable damage.

Flanged Deep Groove Round Bearings

Some deep groove ball bearings come with a flanged outer ring, which works in a similar way to a snap ring on typical ball bearings. The flange enhances the bearing's running performance and also is likewise less complicated to device because of the simpleness of the housing birthed. Flanged deep groove round bearings are excellent for birthing axial loads, such as in tube ends or on belt overview rollers. Some versions even have swivel real estate to permit minor imbalances as well as much better axial loads.

Double-Row Deep Groove Sphere Bearings.

The double-row design permits a significantly higher tons bring ability while still maintaining the bearing's low rubbing features. Double-row bearings are usually just slightly larger than their single-row counterparts, making them practically as versatile and practical. The major disadvantage of double-row deep groove sphere bearings is that they do not come with seals or guards, though some might be fitted with cages. These cages aid with installation as well as assembly however are susceptible to mechanical anxieties throughout operation. It's crucial to pick the right type of cage for the details application, particularly as some cage materials are sensitive to certain lubricating substances.